Adjusting the clutch on your Moke is quite simple - but it helps if you understand what you are doing and why.

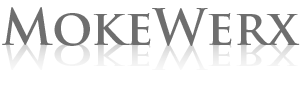

There are only two adjustments on a Moke clutch - the clutch arm stop bolt and the overthrow nuts. Here are the important parts as far as adjustment is concerned.

The most important is the clutch arm stop bolt which provides clearance between the thrust bearing and the diaphragm. Too much clearance and you will waste pedal travel and crunch gears - too little and the thrust bearing will be turning constantly and wear out.

The overthrow nuts are a safety feature to prevent excessive travel of the diaphragm which can cause major engine damage. Too tight they can damage the actuating mechanism - too loose they won't help if something goes wrong.

Clutch Arm Stop Bolt

First step is to unlock the overthrow nuts and back them off so they don't interfere with the adjustment. You will need a thin 15/16"(24mm) open end spanner to hold the inner nut.

Next remove the return spring from the slave cylinder. Be careful doing this, as it is quite strong and can slash your hand if it lets go. The safest way is to get a piece of wire through the bleed nipple end of the spring and pull towards the radiator, or a loop of wire and lever it through the exhaust manifold with a long screwdriver.

Now just pull out on the clutch arm until it stops. You don't need to pull hard on the arm - just take up the slack.

While holding the arm out, check the gap between the stop bolt and the arm.

The factory clearance is 20 thou or 0.5mm. Adjust the bolt to suit and lock with the nut.

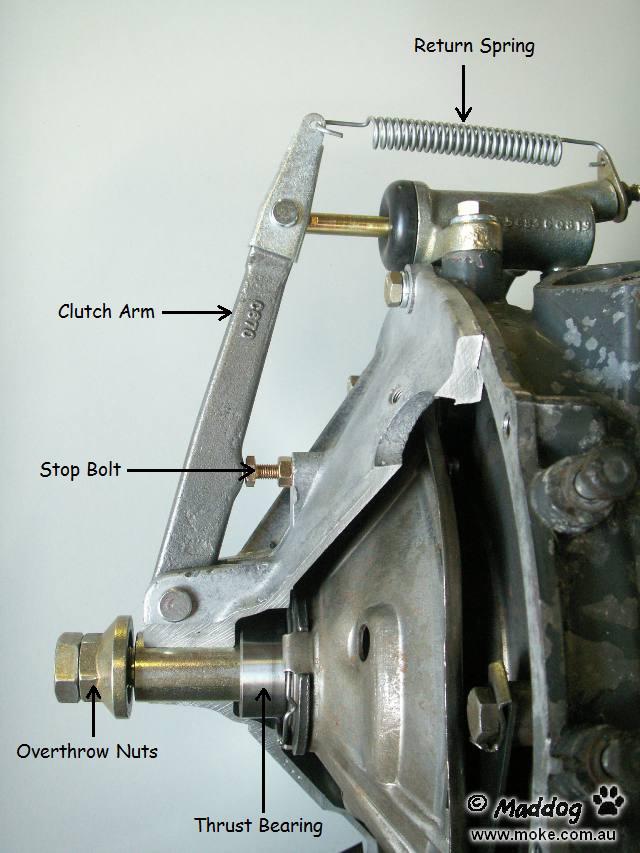

This will mean only a few thou clearance between the thrust bearing and the flywheel/diaphram as shown below, but that's all it takes to stop it turning.

This is even more important now that the good flat face Timken bearings are no longer available.

Replace the spring and you're done. If you don't have a spring, you need to get one. This is all that returns the arm after the diaphram stops pushing, and keeps the thrust away from the flywheel.

Overthrow Nuts

These have always been a bit of a mystery, and a lot of people say you can throw them away. Truth is they will probably never do anything, but if something does go wrong they can save your engine from major damage to the thrust bearings - or even worse, snapping the centre cap. But if properly adjusted there is absolutely no downside to leaving them on. They are of less use with a lightened flywheel, but still good insurance.

To adjust, make sure you have adjusted the arm stop bolt first. Now get an assistant to push the clutch pedal hard to the floor. Spin the inner nut up until it hits the clutch cover.

The manual will tell you to do the nut up one more flat - but my preference is to back it off a bit so you have 0.5 to 1mm clearance. At this the nuts will still do their job if needed, but can't interfere with the operation of the clutch.

Note that this clearance is with the pedal hard to the floor. If the nuts are too tight 9 times out of 10 you will bend the ball on the end of the clutch arm.

Once you are happy with the clearance, hold the inner nut with a thin spanner and tighten the lock nut with a second spanner using a scissor action where you squeeze the two together. They need to be tightly locked together, otherwise they will turn. If they vibrate into the housing, you will almost certainly break something!

Maintenance

The clutch will lose clearance as it wears, so the adjustment needs to be checked regularly. But you have to admit - it's not hard to do!

Adjustment is important, but also unlikely to stop the crunching when you change gears - that is usually caused by wear in the in the hydrualic or mechanical linkages. There are lots of wearing parts, and all of them need to be checked and replaced if necessary.