Heres a simple bracket that helps when lifting the engine out of your Moke. Easy to make too!

These brackets have been around for years in various forms. The idea is the engine will tip back as it's lifted, allowing the diff housing to clear the subframe. You can alter the dimensions to suit the materials you have - as long as you keep the lifting point roughly over the dipstick hole.

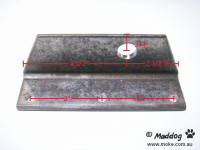

This one is a peice of 2" X 2 1/2" angle 1/4" thick, but 50mm X 50mm will be okay and a lot easier to find. It should be at least 5mm thick so it doesn't bend - but no more than 6mm or you will run out of thread on the head studs. Total length is 7" or 180mm.

The head studs are exactly 3" apart (or approx 76mm) and 3/8 diameter. If it won't go on, drill the end holes slightly larger until it does. These holes need to be 1/2" from the edge so the bracket clears the rocker cover. The hole for the shackle is 1" off centre towards the flywheel. The size of the hole is up to you, but mine is 3/4". It needs to have a bit of room to move around, but not so close to the edge it can pull out.

Here's the layout I used -

Enjoy!!